With the booming development of IoT, AI and edge computing technologies, and the ability to manage large amounts of process and machine data to help the manufacturing industry face fierce market competition, Jeteng Intelligent is a big data analytics solution provider that focuses on data evaluation, integration, visualization and analysis. It also combines AI to provide various smart monitoring and smart manufacturing solutions.

Jeteng Intelligent CEO Shao-Chung Hsu previously worked in semiconductor wafer foundries, accumulating crucial experience in wafer foundry operations and gaining significant expertise in the trend of data-driven smart manufacturing. Founded in 2015, Jeteng Intelligent noticed around 2017 that customers were beginning to request the integration of AI functionality, indicating high market expectations for AI. By 2019, the entry barrier for image AI was no longer prohibitively high. Following the wave of technical validation, the application advantages of AI models would lie in prediction and diagnostics.

However, Hsu Shao-chung discovered that smart manufacturing requires complete data to be truly effective. Considering the current state of Taiwan's industries, he prioritized the semiconductor and panel industries, using AI image recognition technology and diverse data-driven smart applications to build the company's main service areas for long-term development.

AOI Big data analytics assists in streamlining hospital drug dispensing processes.

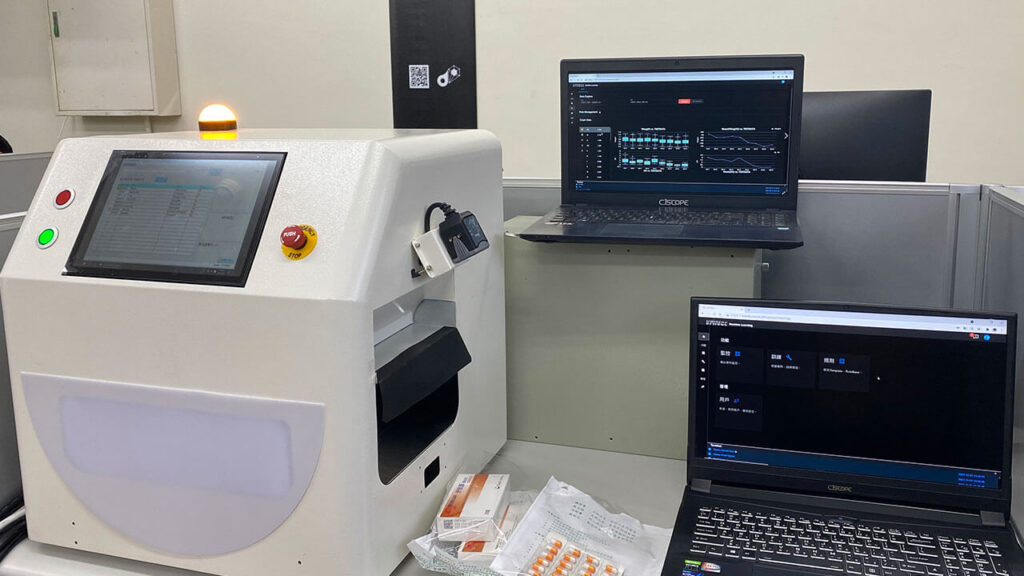

As the manufacturing industry began to use AOI and big data analytics to improve process yield, Jeteng Intelligent discovered that there were similar applications in the medical settings of hospitals, such as drug dispensing machines and processes. So they collaborated with general hospitals such as En Chu Kong Hospital and Tri-Service General Hospital to verify that AI was used to assist the dispensing process at the hospital's dispensing station. AOI was used to identify drugs in cellophane bags. Because the shapes of the drugs were sometimes very similar in color and appearance, the training process of the AI model became very large, and they even struggled with lighting adjustment and image sampling.

To facilitate cross-industry applications in AI drug testing machines, Jeteng Intelligent participated in the "Technology for Pandemic Response 2.0" project, jointly launched this year by the National Center for Information Technology and Taiwan Smart Cloud (TWS) at the National Applied Research Laboratories, to train its drug identification model.By integrating and utilizing the high-speed cloud computing resources of up to 80 GPUs on the TWCC platform, the training speed of AI models is significantly improved.Furthermore, TWCC's cybersecurity features are most noteworthy, providing highly trusted services to domestic hospitals. It has already begun verification work at the front line of medical care and has stored a large number of images of the appearance of both health insurance and non-health insurance drugs, showing significant development potential for smart healthcare applications.

Designed for engineers Accelerates Enterprise with analytics platform

Before venturing into the medical field, Jeteng Intelligent Services prioritized semiconductors and panels, serving clients across various industries including wafer foundries, panel manufacturers, PCB manufacturers, petrochemical and plastics manufacturers, electronic assembly manufacturers, and frequency component manufacturers. Some clients were in the early stages of digital transformation and were beginning to collect data; others already had ample internal experience in AI model training, but under the time pressure and efficiency requirements of the manufacturing process, it was difficult for engineers on the production line to retrain AI models within the constraints of time and tight production schedules.

Therefore, Jeteng Intelligent provides a fairly complete AI model. When customers experience reduced efficiency or inaccurate old AI models due to machine maintenance and adjustments, process engineers can choose to use a small amount of new data to complete a simple AI training mechanism within a limited time, allowing the process to quickly return to production schedule. This is an effective on-line AI solution, which is what Xu Shaozhong emphasizes as "building an AI management platform for engineers."

In some manufacturing processes, AI has achieved very high accuracy, but it cannot withstand a process defect rate of less than 1%. Engineers immediately take action to change it to a rule-based setting. Therefore, Jeteng Intelligent's solution must be a product that combines AI models with rule-based settings, because the ultimate goal is to maximize the benefits of mass production schedule and yield.

Currently, during the product introduction process at Jeteng Intelligent, the initial setup of the first machine typically takes a considerable amount of time, averaging about six months of collaboration with the customer's engineering department for testing and verification. This is followed by the implementation of the management platform. Because 100 precision machines may have more than 100 AI models, the management platform enables close monitoring and ongoing process control, allowing customers to freely integrate a large number of high-precision machines.

Currently, Jeteng Intelligent's AI solution operates and is fine-tuned on the client side using a private cloud architecture. In the future, it will provide a large-scale service platform using a Software as a Service (SaaS) model. To maximize the performance of the AI management platform, the product can even use AI models developed by customers themselves, or add some rule-based settings. This kind of flexible configuration is most needed for the control of large precision machines in the production process. When the machine parameters need to be very precise, sometimes AI assistance is insufficient to improve the yield. In this case, process engineers can use their past experience values to improve the yield, which will help improve the yield output in various fields.

Source:National High-Speed Network and Computing Center, National Research Institute